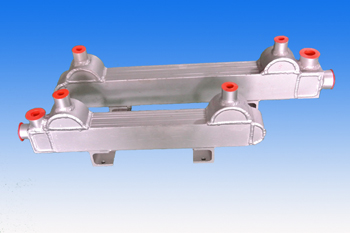

Aluminum plate-fin heat exchanger, developed by a Professor from Nanjing University of Technology, is specially used for cooling the barrel of screw extruder. By transferring the heat from the system, it will effectively prevent the decomposition of the polymer caused by superheating.

Advantages

Aluminum plate-fin heat exchanger offer tremendous benefits than traditional shell and tube heat exchangers::

More compact structure, less install space;

High reliability and no leakage due to all welded structure;

Higher heat transfer efficiency;

Lower cost;

Longer useful-life;

Technology parameters

Table 1 Performance parameters of aluminum plate-fin heat exchanger

|

specifications parameters |

ACW35 |

ACW50 |

ACW65 |

ACW75 |

ACW95-1 |

ACW95-2 |

|

Pump capacity of hot water(oil) (m3/h) |

1.3 |

2.1 |

2.5 |

4.7 |

7.2 |

10.8 |

|

Pump capacity of cooling water (m3/h) |

3.2 |

5 |

6.1 |

11.3 |

17.4 |

26 |

|

Inlet temperature of hot water(°C) |

57 |

57 |

57 |

57 |

57 |

57 |

|

Outlet temperature of hot water(°C) |

≤45 |

≤45 |

≤45 |

≤45 |

≤45 |

≤45 |

|

Inlet temperature of cooling water(°C) |

32 |

32 |

32 |

32 |

32 |

32 |

|

Outlet temperature of cooling water(°C) |

37 |

37 |

37 |

37 |

37 |

37 |

|

Heat transfer area(m2) |

0.61 |

0.89 |

1.3 |

2.13 |

2.80 |

4.4 |

|

Cooling capacity(kW) |

18 |

28 |

35 |

65 |

100 |

150 |

|

specifications parameters |

ACW35 |

ACW50 |

ACW65 |

ACW75 |

ACW95-1 (100kW*) |

ACW95-2 (150kW*) |

|

|

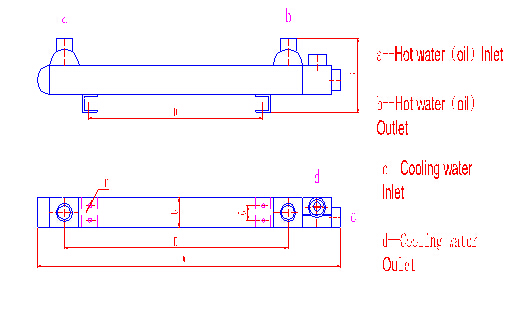

Overall dimension |

A(mm) |

580 |

640 |

720 |

945 |

972 |

990 |

|

B(mm) |

195 |

205 |

205 |

240 |

245 |

280 |

|

|

C(mm) |

56 |

64 |

64 |

83 |

99 |

123 |

|

|

Installing dimension |

D(mm) |

240 |

260 |

340 |

550 |

570 |

540 |

|

E(mm) |

360 |

410 |

490 |

710 |

710 |

710 |

|

|

F(mm) |

4×Φ11 |

4×Φ11 |

4×Φ11 |

4×Φ11 |

4×Φ11 |

4×Φ11 |

|

|

G(mm) |

40 |

40 |

40 |

40 |

40 |

80 |

|

|

Joints dimension |

a |

G1/2 |

G1/2 |

G1/2 |

G1 |

G1 |

G |

|

b |

G1/2 |

G1/2 |

G1/2 |

G1 |

G1 |

G |

|

|

c |

G3/4 |

G1 |

G1 |

G |

G |

G |

|

|

d |

G3/4 |

G1 |

G1 |

G |

G |

G |

|

|

Weight(kg) |

4.6 |

5.9 |

6.7 |

10.5 |

13.4 |

19.0 |

|

Table 3 Examination parameters of aluminum plate-fin heat exchanger

|

Technology data |

Hot water(oil) side |

Cooling water side |

|

Lowest working temperature |

-160°C |

|

|

Highest working temperature |

225°C |

|

|

Designing pressure |

1.2MPa |

1.2MPa |

|

Hydraulic test pressure |

1.8MPa |

1.8MPa |

|

Air test pressure |

1.32MPa |

1.32MPa |

Storing:

1.Keep the interior of the cooler clean and dry.

Installing:

1.This product should be flatly installed.

2.The dimension of the connecting tubes should be consistent with that of the heads.

3.Liquids in the cooler should form counter current flow.

4.The connecting tubes should be installed carefully. Screwing moment should be in 55~60Nm,in order to prevent the leakage.

5.Never tempestuously shake or expand the connecting tubes.

Application:

1.to insure the smooth flow of the liquids in the cooler;

2.check to prevent the accident of leakage;

3.A filter is suggested at the inlet of the cooler when the cooling water contains relatively more impurity. And if the rigidity of the cooling water is relatively high, a softening procedure is needed.

4.The pressure of the pump of cooling water must be more than 4 bars to ensure the capacity of the cooling water.

Customer service

We are ready to offer all-around service. Our equipments, designing projects and services are all for the improvement of client’s products. Special services are here for your special requirements.

Contact us

Nanjing RCT Thermal Energy Equipment Co., Ltd

Tel: 86-25-83243112

Fax: 86-25-83600956-20